Quality Through Commitment

Here at Liberty Electronics®, our quality strategy revolves around the needs of our customers and their specific product needs. Through operating with Lean Manufacturing principles and utilize Six Sigma tools across the value stream, Liberty strives to achieve zero defects on all of our assemblies.

Continuous improvement is our priority. Certified Six Sigma black belts are on staff, and projects are worked under the auspices of our Operational Excellence Council in areas such as process control, defect prevention, cycle time reductions, and corrective actions.

Quality Through Automation

Quality and validation checkpoints are embedded into the process of building every assembly to ensure the highest amount of efficiency and functionality. Multiple validations and tests are performed to ensure our products meet our customer specifications and high-quality standards. All of our tooling and machinery is consistently monitored and calibrated to ensure accuracy and precision.

Automation plays a key role in reducing variation in our assemblies. Liberty utilizes various high-end machines to automate processes that otherwise could slow down productivity and increase variation. This machinery assists with processes such as:

- Cutting and stripping wires

- Pull-testing

- Inspecting pin retention

- Crimping contacts

- Twisting wires

- Taping

- Applying shrink tubing

- Circuit testing

- Testing crimp quality.

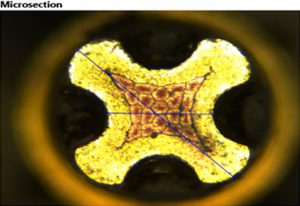

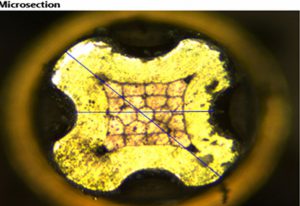

WA22/ K13-1

Position #5

24 AWG Setting

“Over-Crimping” 22 AWG

Crimp Depth 0.0311”

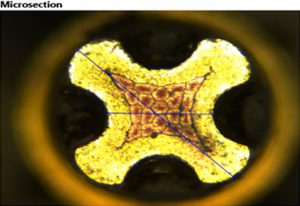

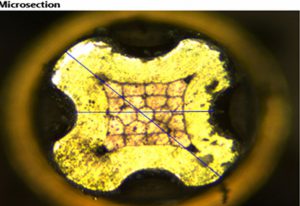

WA22/ K13-1

Position #6

22 AWG Setting

” Goal Crimping” 22 AWG

Crimp Depth 0.0348”

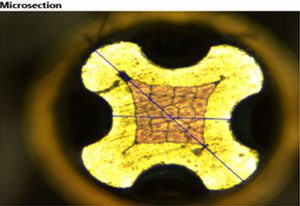

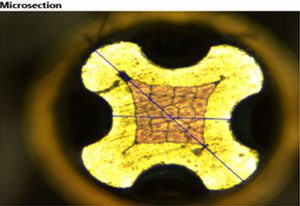

WA22/ K13-1

Position #7

20 AWG Setting

“Under-Crimping” 22 AWG

Crimp Depth 0.0397”

Quality Through Standards

Liberty Electronics® only works with authorized manufacturers and distributors with proper documentation to verify compliance. This ensures the quality meets our standards in order to provide the highest quality products for our customers with zero tolerance for counterfeit parts.

Employees must undergo certification courses in correlation with the products they will assemble. They must always obtain an updated IPC-A-610 Application Specialist certification. To prioritize and expedite this process, Liberty has on-site IPC/WHMA-A-620 certified IPC trainers on staff to ensure compliance with regulations and certifications.

Liberty Electronics® is AS9145 compliant.

We operate under these certifications:

If concepts and requirements are available of your assembly needs, we welcome the opportunity to review them with you, at your convenience.