Liberty Electronics® understands the importance of minimizing time to market. Lean development processes and an emphasis on Rapid Prototyping enable Liberty to respond quickly to customers’ new product and process needs. Liberty has a Prototype Team, facilities, and state-of-the-art technology that are dedicated to new development work. The team consists of senior technicians who have decades of experience collaborating with customers on challenging new projects. The team’s expertise, tools, and commitment have resulted in a long list of successful development programs with prime contractors and OEM’s. Whether you’re faced with cost, reliability, performance, lead time or other development challenges, Liberty Electronics® as the capability and commitment to help achieve your goals.

Engineering

- Computer-Aided Design

- Solid Modeling

- Molds

- Harnesses

- 3D Printing

- Model Shop

- Digital

- Physical

Dedicated Prototype Team & Facilities

Technicians:

- Experience: 30 years (Avg.)

- IPC-620, Certified

- J-STD-001, Certified

Quality Assurance:

- IPC-620, Certified

- IPC-610, Certified

- J-STD-001, Certified

Materials:

- Qualified Vendor Base

Resources:

- Dedicated Area (1200+ Sq. Ft)

Information Security:

- NIST/CUI Protocols

- ITAR – EAR Registered

Configuration Management:

- Oracle-Agile ERP System

- Document Control

- History Logging-Including Redlines

State-of-the-art Technology – Machinery

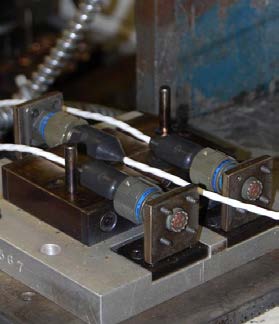

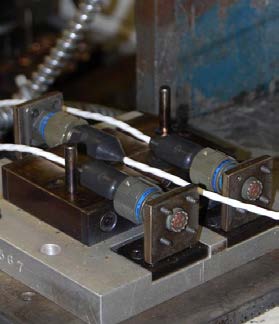

Automated Cut, Strip, and Crimp

- Analysis

- Validation

Machine Braiding

- 16, 32, 64 Bobbin

- Vertical

- Horizontal

Laser Wire Stripping

Resistance Soldering

- 36 AWG – 777 MCM

Ultrasonic Welding

- Shield Termination

- Splicing

- Wire Termination

Additive Manufacturing

- Prototype Molds

- AS9102 Inspection Fixtures

- Component Production

State-of-the-art Technology – 3D Printing & Scanning

3D Printing – Additive Manufacturing

- ABS-M30 (6 available colors)

- ABS-M30i (medical and pharmaceutical rated

- ABS-ESD7 (ESD Rated ABS)

- ASA – UV Stabilized ABS (10 available colors)

- Antero 800NA (PEKK)

- Antero 840CN-ESD (Material Beta Test Site)

- FDM Nylon 12, 12CF-Carbon Fiber (black)

- Polycarbonate (White)

- ULTEM 1010

- ULTEM 9085

- Build Envelope: 14” x 12” x 12”. (2016 cu/in)

- Accuracy: ±.005 in. overall , or ± .0015 in/in

- Layer Thickness options : .005”, .007”, .010”, .013”

- Vero (Acrylic Like) (6 colors)

- Polypropylene-like

- Tango (Rubber-like )(3-durometers)

- High- Temp RGD525 (175° F)

- Hardness to Shore D-86

Design and Reverse Engineering Software

- SolidWorks Premium

- AutoCAD LT2019

- Artec Studio

- Artec EVA and Spider 3D Scanners

- Geomagic for SolidWorks

State-of-the-art Technology – Testing

- Crimp Analysis (sectional)

- Mechanical Strength Pull Testing

- Environmental Testing

- Particle Contamination Testing

- Thermal Cycle Testing

- Mechanical Cycle/Testing

- 3D Modeling Mechanical Failure Analysis

State-of-the-art Technology – Unique Processes

Over Molding and Encapsulation:

- Transfer Presses

- EFD Units

- Autoclave

- Quick Turn Molds

- 3-D Printed, High-Temp Polymers

- Steel

- Aluminum

Machine Braiding:

- 6, 32, 64 Bobbin

- Vertical

- Horizontal

Laser Wire Stripping

Resistance Soldering

Ultrasonic Welding/Wire Termination

Experience Highlights

MRAP Development Project

- 26,000 MRAP Assemblies Shipped

- 28,000 Total Assemblies Shipped during a

- 9 Month Period 5,300 Assemblies Shipped in 1 Month

- 39 Top Level Assembly P/N’s

- 1,200 Engineering Hours In First Month

- Incorporated Red Lines in Configuration,

- Changes w/o Delivery Interruption

- Processed 332 ECO’s In 9 Months

MISSILE Development Projects

- AGM-114- Hellfire

- BRIMSTONE

- RIM-161 – Standard Missile 3 (SM-3)

- ATCM(s) – Missile System

- AGM-65 – Maverick

- AGM-176 – Griffin Missile System

- AIM-9X/Sidewinder

- AI3 – Accelerated Improved Interceptor Initiative

- AIM-120 – AMRAAM

- M220-TOW – Anti-Tank Guided Missile System FGM-148

- Javelin – Anti-Tank Missile

- JAGM – Joint Air-to-Ground Missile

- JCM – Joint Common Missile

- NLOS -Non-Line of Sight Missile System PAVEWAY – Laser Guided Missile

- TRIDENT – Submarine Launched Ballistic Missile

TORPEDO Development Projects

- Mk-48 ADCAP Torpedo

- Mk-46 Lightweight Torpedo

- Mk-50 Lightweight Torpedo

- Mk-54 Lightweight Torpedo

- Trident ll Missile System

Rapid Prototyping

Liberty Electronics has spent the last 30 years establishing its place as an indispensable source for electronic components for a wide range of industries. Our products have formed essential parts in cutting-edge aerospace and military/defense equipment, and we’ve proven ourselves to be invaluable partners for OEMs across the U.S.

We regularly publish the latest news and industry insights at our blog, Wired Success, covering topics ranging from single-source procurement to best practices in boxing and shipping. Contact us to learn more about how our wire harness and electrical cable assemblies will benefit your next project.