Can You Have Your Cake and Eat it Too?

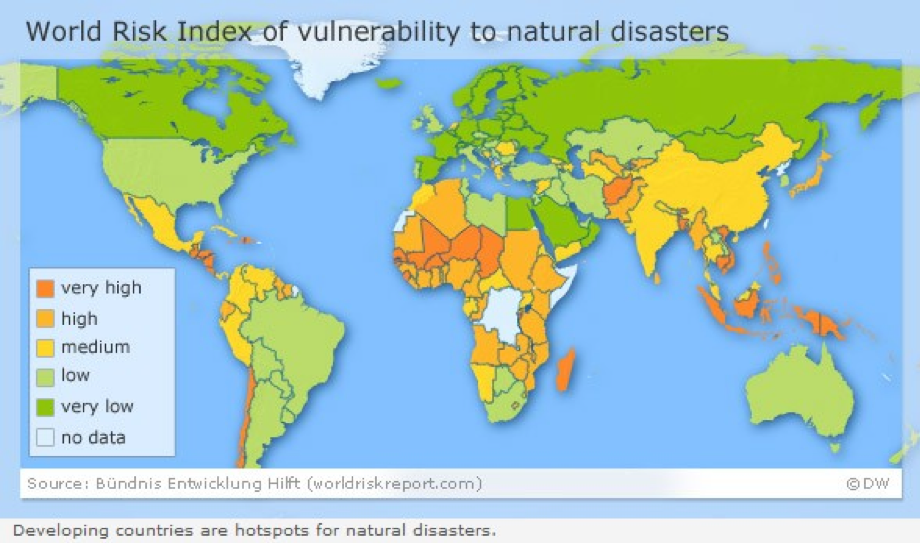

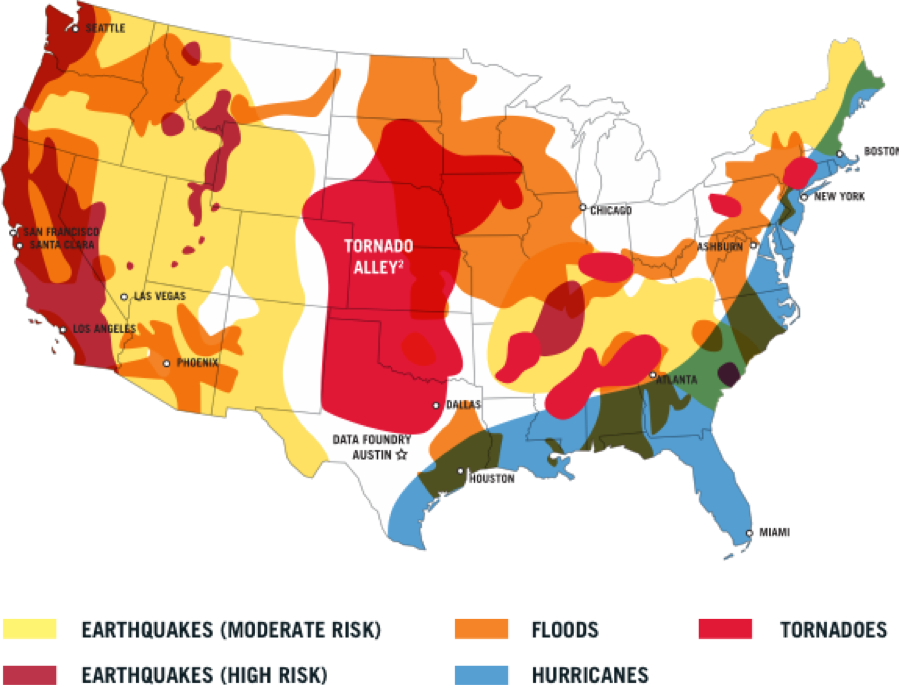

Increasing tariffs, changing international trade deals, rising labor and overhead rates, corruption and fraudulent practices, and theft of intellectual property have all played havoc in recent years with supply chain efficiency. At the same time supply chain resiliency has been acutely tested by natural disasters from earthquakes and tsunamis to hurricanes, flooding, and even ash from volcanoes; threats of cold and hot wars, and crime; and most recently of course by COVID-19 pandemic fears.

The frequency and scope of recent events have many asking – “Is it possible to achieve both optimum supply chain efficiency and resiliency”?

Manufacturers See Reshoring as an Option

Data shows that more US companies believe that the answer is yes and that they are looking to reshore their supply chains to do this. According to a recent Thomas Industrial Survey, almost half of US manufacturers are now looking to source domestically. According to research done by The Reshoring Initiative, the top reasons for reshoring include:

- Lead time

- Higher product quality and consistency

- Rising offshore wages

- Skilled workforce

- Local tax incentives

- Image of being Made in the USA

- Lower inventory levels, better turns

- Better responsiveness to changing customer demands

- Minimal intellectual property and regulatory compliance risks

Factoring in the Total Cost of Ownership

As Deming postulated in his 14 Points, purchase price alone is a poor metric to evaluate purchasing decisions, and that’s especially true in this environment. Total Cost of Ownership (TCO) numbers are increasingly being used to account for supply chain efficiency and resiliency factors and to improve supply chains. Parameters like shipping costs, packaging costs, inventory carrying costs, rework, warranty, risk of supply interruptions, international travel, risk of theft and fraud, etc. are taken into account to provide a much more accurate view of the total cost.

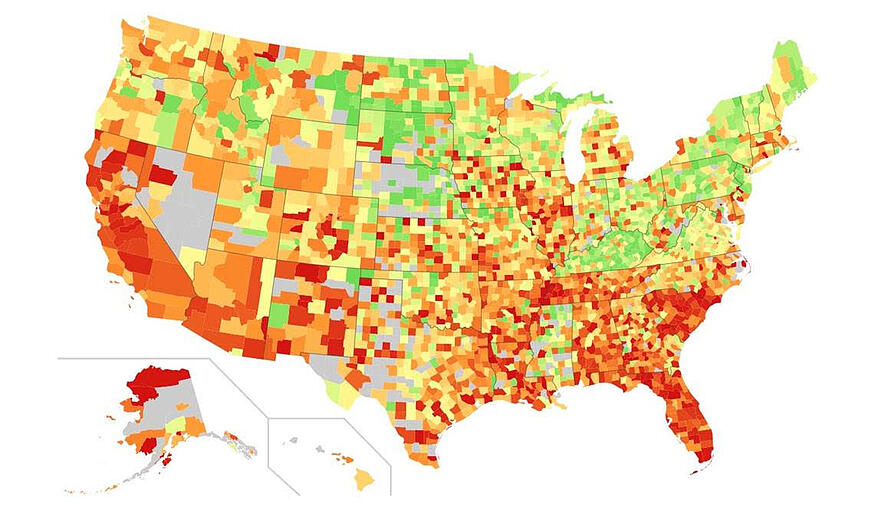

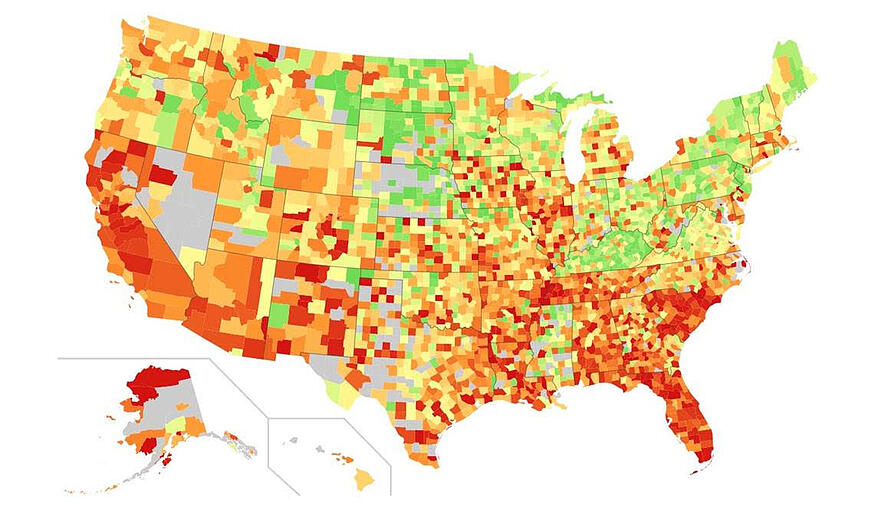

Using Total Cost of Ownership, parts of the globe that were previously thought to be “low-cost regions” are being seen in a different light. Conversely, places like the United States, and specifically certain regions of the United States, that were assumed to be uncompetitive, are now looking very favorable.

More and more companies are finding that by making sourcing decisions based on the lowest total cost of ownership they can indeed achieve both optimum supply chain efficiency and resiliency.

If you are looking for a US-based contract manufacturer that is located in a favorable location and that has a demonstrated record for providing the lowest cost of ownership we invite you to consider Liberty Electronics®.

For further reading: Reinvesting and Redefining American-Made: Now is the Time to Reshore Manufacturing